At the end of 2020, Dutch greenhouse company Schneider Youngplants moved its production nursery and head office from Ridderkerk to Woudrichem. This meant they exchanged their old wide-span greenhouse for a new Venlo greenhouse. The company called in Ridder to advise them on the best screening plan for their new set-up.

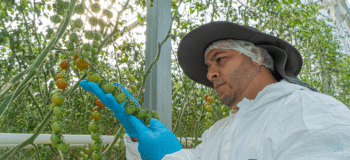

Schneider Youngplants specializes in propagating young plants from seeds and cuttings. Their range includes annuals, biennials and perennials, with an emphasis on cyclamen and vegetable plants. The company had to leave its old location in Ridderkerk to make way for another development, which also meant leaving behind its wide-span greenhouses fitted with roller screens and one horizontal screen. They found a new location in Woudrichem. Last year, KG Greenhouses built them a new 3.5 hectare Venlo greenhouse with six compartments, as well as an area for business operations and processing. Because the new greenhouse is a different type to the old one and, above all, allows more light to enter, Schneider Youngplants wanted to make sure they were fully informed about all the screening options. KG Greenhouses invited Ridder to advise on screen fabrics and drive units at the new site.

Light restriction screen

As screening specialist Johan van Erven from Ridder explains, the RLR 99 FR W screen was chosen as the best light restriction screen for the cultivation compartments. This was due to the supplemental lighting in use in those five compartments. ‘This is Ridder’s ultimate light restriction screen which, thanks to its special knitted structure, has good moisture permeability and a stable structure.’ The sixth compartment in the greenhouse has been fitted with a blackout screen for growing day-length sensitive crops. The RBO 100 FR WB+B screen was chosen for that compartment, explains Van Erven. ‘This fabric also allows moisture to pass through and has a very stable structure.’

Ridder Variable Screening

Because Schneider Youngplants mainly cultivates young plants, it is important that the incoming light can be controlled. This was the reason why an RLD 45 FR O screen was installed for the lower section of the installation. This screen enables the grower to screen out incoming light properly in the spring and autumn. In the summer, Ridder Variable Screening (RVS) is used. ‘It’s a very robust solution that enables perfectly graduated screening of incoming light,’ says Van Erven. ‘By closing the RLD 45 FR O screen completely, 45 percent of the incoming light is screened out. The open structure of the fabric ensures that warm air from the greenhouse can be discharged through the fabric and out through the vents. The Ridder Light Diffusion (RLD) screens not only provide protection, but they also diffuse the light that is allowed in. The top screen (RLR or RBO) enables you to keep even more light out of the greenhouse. The bands of shadow that are created are largely cancelled out by the light-diffusing effect.’

Ridder Drive Systems

Finally, due to the company’s rural location, Schneider Youngplants also believes it is important to limit light emissions through the sidewalls of its greenhouses. For this, Ridder recommended the RBO 100 R FR W screen. This is a roller screen that is effective and easy to install, but also has a very stable structure and hardly suffers from any shrinkage. The picture was completed with a selection of Ridder RW-drive units, Ridder rack and pinion systems, Ridder Power Rollers and Ridder RB tube motors for all the air vents and screen installations: the best possible screening plan for Schneider Youngplants.