Effective

recirculation

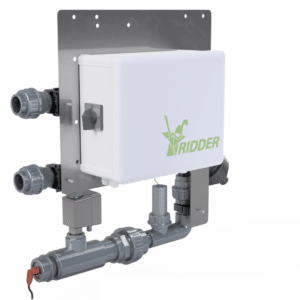

Water and fertilizers cost money. So in order to get the most out of every drop of water and minimize the consumption of fertilizers, greenhouse growers recirculate as much water as they can. But it is vital to treat the water properly both at the beginning and the end of the cycle. In order to make this process as efficient as possible, Ridder developed the Ridder VitaLite disinfection unit.

The Ridder VitaLite uses ultraviolet light to eliminate harmful bacteria, fungi and pathogens in the water. It is a reliable method and does not depend on the use of chemicals. The Ridder VitaLite’s smart design makes it simple to install this safe, automated and environmentally friendly method of disinfection in any type of cultivation. This enables growers anywhere in the world to recirculate their irrigation water safely, reducing their consumption of water and fertilizers and helping to make our environment more sustainable.

The Ridder VitaLite has a highly efficient capacity thanks to its use of flow plates in the UV reactors. This ensures that the disinfection process is always effective, even at higher flow rates. The Ridder VitaLite uses low-energy, low-pressure UV lamps.

'With the Ridder VitaLite I can safely reuse my water and fertilizers'

Dirk & Keith Vis and Devin Jaspers, Canadian tomato grower, Sunshine Greenhouse

The benefits of the VitaLite at a glance

|

100% disinfection |

No chemicals |

Efficient |

Low power consumption |

Safe recirculation of water and fertilizers |

|

|---|---|---|---|---|---|

|

Ridder VitaLite |

|

|

|

|

|

1-on-1 with a water management expert

Do you need to optimize your water recirculation in your greenhouse, but don’t know where to start? Our water management experts can help you pinpoint your specific problem and guide you through a solution. Request a one-on-one today.

Contact us