Things are going well in Vietnam – in 2017, the GNP of the country with its 96 million inhabitants grew by 6.8%. This meant the Vietnamese economy had its fastest growth in the last ten years. As a result of the rapidly-growing middle class and the increasing demand for high-quality, local and safely-produced products, the Vietnamese agriculture and horticulture sector offers an attractive investment climate. Wage rises and a lack of knowledge however do present challenges.

Agrofood development

Various Vietnamese investors are showing interest in injecting their capital into the resurgent domestic agriculture and horticulture sector. There is much demand for agricultural products and some big industrial heavyweights see a chance to invest in the horticulture chain. These developments are associated with the necessary contributions from Vietnam’s export partners. Although the Vietnamese government designated the Netherlands as a preferred partner for agrofood development, many Japanese and Korean partners are also involved in projects. These countries are interested in Vietnam’s export potential and realise that further technological development of the Vietnamese horticulture sector is needed.

Asia’s market garden

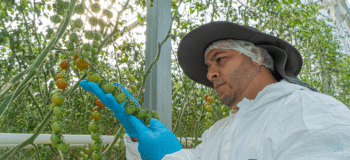

Jan Hoogewoning, Business Development Manager for Southeast Asia at Ridder, is following the developments in Vietnam closely. He notes that much more knowledge and support will be needed to help the local horticulture sector get going. “Vietnam, and particularly the higher altitude southern region round Da Lat, have everything that’s needed to become the primary horticulture area in Southeast Asia. There is a favourable climate for greenhouse cultivation and also an increasing demand for safe and year-round cultivated products. However, many growers are not yet capable of raising a high-quality, uniform and food-safe product. They lack the right technological resources, and also frequently the knowledge and insight to invest in these. Often they don’t know all the possibilities. ”

“Bringing all data together in one report, to create a clear overview”

Error-free

What Jack is particularly proud of is the mobile weighing scale he developed in cooperation with Ridder. One mobile weighing scale for the old carts with a narrow track and one for the new carts with a wide track. He helped Ridder develop the procedure and the protocol embedded in the weighing scales. “The scale features a cart recognition system. Each morning everyone choses a cart. Then when you roll the cart onto the weighing scale all you have to do is enter the row number and everything else is done automatically. That makes a huge difference in terms of preventing mistakes. If you have to enter the cart number, personnel number, weight and even the row number yourself, there are many opportunities for errors.” Sweet Lions has been using the system since 2000, and they are still very happy with it. It works great.” Very few mistakes are made entering the harvests.”

Significant time savings

In addition to significantly reducing the chance of errors, Jack says another big advantage of the mobile scales is time savings. “It saves a tonne of time that would otherwise be spent manually entering data into the computer. Besides that, we have a lot of workers. Sometimes we have 60 pickers working at the same time. The last thing we want is for queues to form at the weighing scales. That kills your efficiency. With the mobile weighing scale, pickers can weigh straight away, and that makes a big difference.”